The Secretariat of Defence Industries (SSB) was founded in 1985 as the Defence Industry Development and Support Administration Office (SaGeB) under the Ministry of National Defence in accordance with Law No. 3238. The SaGeB was tasked to determine the policies for the establishment of the defence industry infrastructure throughout new mechanisms having the necessary authority and responsibility in implementing those policies. Subsequently, the SaGeB was restructured as the Undersecretariat for Defence Industries (SSM) in 1989. SSM was affiliated to the President of the Republic of Türkiye in December 2017 and renamed as Secretariat of Defence Industries (SSB) in July 2018.

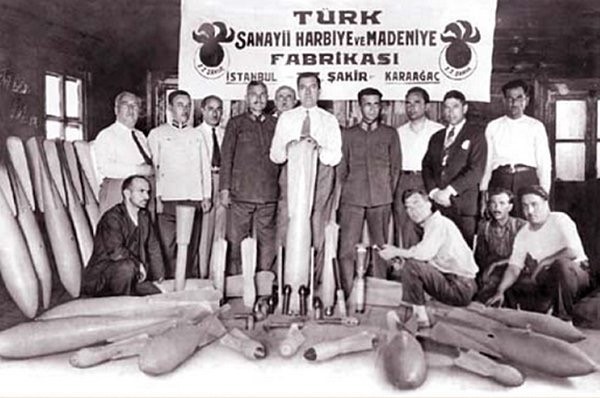

Machinery, craftsmen and workmen transferred discretely from İstanbul and its surroundings at the end of World War 1 played a crucial role in winning the War of Independence. Small scale and simple workshops in Ankara and environs and Erzurum not only provided light weapons and ammunition but also helped lay the foundation for a sound local defence industry infrastructure.

Machinery, craftsmen and workmen transferred discretely from İstanbul and its surroundings at the end of World War 1 played a crucial role in winning the War of Independence. Small scale and simple workshops in Ankara and environs and Erzurum not only provided light weapons and ammunition but also helped lay the foundation for a sound local defence industry infrastructure.

General Directorate of Military Facilities was set up in 1921. Establishing a weaponry and ammunition production capability was discussed for the first time during the İzmir Congress of Economics. Consequently a number of facilities were set up in Ankara and its surroundings between 1924 and 1943. In addition, a privately owned small facility producing pistols, 81 mm mortar and its ammunition, explosives and pyrotechnics, provided support to the Turkish Armed Forces during World War 2. In the meantime Gölcük Shipyard was set up for the maintenance of Yavuz battle cruiser in 1924 and Taşkızak Shipyard was reactivated in 1941.

Turkish aviation industry was set in motion with the establishment of Tayyare ve Motor Türk AŞ (TamTAŞ) in 1926. The facilities of TamTAŞ in Kayseri started production in 1928 and until 1939, a total of 112 aircraft –15 German Junkers A-20s, 15 US Hawk fighters, 10 US Fledging trainers, 15 German Gotha liaison aircraft –were produced. After completion of the maintenance of the aircraft in the inventory of the Turkish Air Force Command, TamTAŞ suspended aircraft production in 1939.

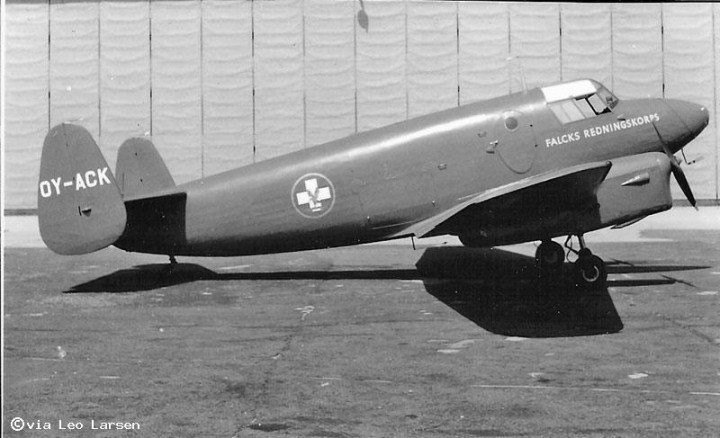

Meanwhile, 24 Nu. 37 aircraft and many gliders were produced in the aircraft facility founded by entrepreneur Nuri DEMİRAĞ in İstanbul in 1936 but this private firm was out of operation in 1943.

Meanwhile, 24 Nu. 37 aircraft and many gliders were produced in the aircraft facility founded by entrepreneur Nuri DEMİRAĞ in İstanbul in 1936 but this private firm was out of operation in 1943.

The first major initiative in the aviation industry was the formation of an aircraft facility by Turkish Aviation Association in Ankara in 1941. Starting production in 1944, this facility manufactured 80 Miles Magister trainer aircraft, two-engine ambulance aircraft THK-10 light transport aircraft, 60 Ugur two-seater trainer aircraft and various types of gliders. The first aircraft engine facility was set up in Ankara, in 1945 and started production in 1948. Several other facilities were founded in Malatya between 1942-43 in order to repair and maintain the aircraft procured from the United Kingdom during World War 2.

Instead of improving the local defence industry, Türkiye's depended on foreign aid and met its defence requirements through and in the framework of NATO during this period of Cold War and military and political polarization. Foreign military aid that started pouring in upon Türkiye’s membership in NATO and soared within a short period, stalled the development of local defence industry which was still at its infancy.

Instead of improving the local defence industry, Türkiye's depended on foreign aid and met its defence requirements through and in the framework of NATO during this period of Cold War and military and political polarization. Foreign military aid that started pouring in upon Türkiye’s membership in NATO and soared within a short period, stalled the development of local defence industry which was still at its infancy.

As a result, efforts for the development of a local defence industry slowed down; orders of Turkish Armed Forces from local suppliers diminished inevitably, and in the end military facilities became a part of the Machinery and Chemical Industry Corporation (MKEK) which was formed as a State Economic Enterprise on 15 March 1950.

However, development of weaponry and military equipment was kept on the agenda by the Research and Development Department formed in 1954 under the Ministry of National Defence and in 1970 development studies of defence industry would be resumed.

It was a period of regional conflicts and the Cyprus issue. Cyprus crises in 1963 and 1967, the Cyprus Peace Operation in 1974, and the arms embargo imposed on Türkiye as a result of this Peace Operation, necessitated the development of a national defence industry. Having suffered a great deal because of its dependence on foreign supply, Türkiye started to seek ways to reactivate national defence industry. During this period when investments based on import substitution were common, production of G-3 and MG-3 rifles by MKEK under German licenses were concrete examples of this policy put into practice.

It was a period of regional conflicts and the Cyprus issue. Cyprus crises in 1963 and 1967, the Cyprus Peace Operation in 1974, and the arms embargo imposed on Türkiye as a result of this Peace Operation, necessitated the development of a national defence industry. Having suffered a great deal because of its dependence on foreign supply, Türkiye started to seek ways to reactivate national defence industry. During this period when investments based on import substitution were common, production of G-3 and MG-3 rifles by MKEK under German licenses were concrete examples of this policy put into practice.

The 1970’s were an era when solid initiatives were put into force so as to establish a national defence industry. As a result of the national reaction to the arms embargo against Türkiye, Armed Forces Foundation was established. Although the Foundation formed enterprises such as Aselsan, Havelsan, Aspilsan thanks to the donations, it was soon realized that the actual need for a contemporary defence industry could not be met through the Foundation alone.

However, regional problems Türkiye faced in the 1960’s, Cyprus crises in 1963 and 1967, the Cyprus Peace Operation in 1974 and the arms embargo following the Peace Operation necessitated the development of a defence industry based on national resources. In 1974 Turkish Armed Forces Foundation was established with this understanding in mind and several investments, though limited, were initiated.

However, regional problems Türkiye faced in the 1960’s, Cyprus crises in 1963 and 1967, the Cyprus Peace Operation in 1974 and the arms embargo following the Peace Operation necessitated the development of a defence industry based on national resources. In 1974 Turkish Armed Forces Foundation was established with this understanding in mind and several investments, though limited, were initiated.

During the 1980's, state initiative was undertaken to realize the modernization of the Turkish Armed Forces and the establishment of a national defence industry based on contemporary technology was determined as the primary goal.

During the 1980's, state initiative was undertaken to realize the modernization of the Turkish Armed Forces and the establishment of a national defence industry based on contemporary technology was determined as the primary goal.

The first step in this direction was taken by the establishment of Defence Equipment Directorate as a state enterprise. However, the shortcomings stemming from its inert status blocked its success and before long Undersecretariat for Defence Industries (SSM) was born in 1985 under Law No:3238.

In the 9th Development Plan (2007-2013), published in 2006, the main objective was set as “the development of a competitive, self-sufficient and flexible production capacity integrated with the national industry, actively contributing to co-production-design and R&D multinational programs”. For that purpose, development of the necessary infrastructure, technological and management capabilities were aimed in order to meet the needs of the defence industry in a secure and stable way.

In the Defence Industry Special Expertise Commission Report 2007-2013, the main sectoral vision was determined as “Achieving an internationally competitive defence industry infrastructure capable of meeting national defence and security needs by developing effective domestic solutions”.

In the Defence Industry Special Expertise Commission Report 2007-2013, the main sectoral vision was determined as “Achieving an internationally competitive defence industry infrastructure capable of meeting national defence and security needs by developing effective domestic solutions”.

With 2006 Strategic Plan (2007-2011), in line with its mission to meet the defence and security requirements of the Turkish Armed Forces and other public organizations, SSM has been restructured as a sole procurement authority that provides indigenous domestic solutions to the country's strategic defence and security needs in line with technological developments, and thus leads a competitive defence industry integrated into the international market.

In the 2010s, in order to meet critical technologies and design capabilities domestically to the maximum extent, emphasis was placed on indigenous design programs under the responsibility of local prime contractors. In the SSM's 2012-2016 Strategic Plan, the vision of the SSM was to make Türkiye superior in defence and security technologies, and the mission was to manage industrialization, technology and procurement programs that will ensure the continuous development of the country's defence and security capabilities.

In this direction, Türkiye's dependence on foreign countries has been significantly reduced with the commissioning of these programs, which aim to prepare the Turkish Armed Forces for the combat environment of the future, to gain competence in defence and security technologies, and to develop platforms and systems domestically that will provide technological superiority. The MİLGEM Corvette, Altay Tank, Atak Attack Helicopter, Anka and Bayraktar Unmanned Aerial Vehicles, Hürkuş Basic Trainer Aircraft, Göktürk-1 Surveillance Satellite, New Type Patrol Boats, Fast Patrol Boats, National Infantry Rifle, Mine Resistant Vehicles, Air Defence and Missile Systems, and many other systems and subsystems are the prominent examples of these efforts to reduce dependency in the defence industry.

In this context, significant progress has been made in the defence sector in the post-2006 period. The turnover of the defence and aerospace sector increased from USD 1.3 billion in 2002 to USD 6 billion in 2006, defence and aerospace exports from USD 247 million to approximately USD 2 billion and R&D expenditures from USD 49 million to USD 1.25 billion respectively. In addition, three Turkish companies are listed in the “100 Largest Defence Industry Companies in the World”.

The 10th Development Plan (2014-2018) has emphasized the need to make the defence industry more competitive, to meet defence system and logistics needs based on indigenous design in an integrated and sustainable manner with the national industry, to increase the share of local content and the share allocated to R&D through the use of appropriate technologies for civilian purposes, and to support network and clustering structures in defence sectors.

The 10th Development Plan (2014-2018) has emphasized the need to make the defence industry more competitive, to meet defence system and logistics needs based on indigenous design in an integrated and sustainable manner with the national industry, to increase the share of local content and the share allocated to R&D through the use of appropriate technologies for civilian purposes, and to support network and clustering structures in defence sectors.

In line with the Development Plan, SSM, in its 2017-2021 Strategic Plan, has set goals and objectives to “make Türkiye a global player in the field of defence and security with its indigenous design and advanced technology capabilities” and to “manage the programs that will ensure the sustainability of the defence industry with a holistic approach by developing capabilities that will increase the power of our country in the fields of defence and security”.

In 2017, the Undersecretariat for Defence Industries, which was directly affiliated to the President of the Republic of Türkiye, was given the status of the Secretariat with the Presidential Decree No. 7 in 2018, and its duties, powers and responsibilities were regulated accordingly. In this context, the main policy of the Secretariat was determined as ensuring the production of all necessary weapons, tools and equipment in Türkiye as much as possible by utilizing the domestic industrial infrastructure to the maximum extent and directing and encouraging R&D activities, especially advanced technology investments.

As of 2018, defence and aerospace turnover has reached to USD 8.761 billion, defence and aerospace exports have increased to USD 2.188 billion, and R&D expenditures to USD 1.448 billion. The number of defence projects carried out by the Secretariat increased to 667, with a contract value of approximately USD 60 billion. In addition, the number of Turkish companies among the “Top 100 Defence Industry Companies in the World” has increased to 5.

Within the framework of the 11th Development Plan, which is also mentioned in the 2019-2023 Strategic Plan of the Secretariat of Defence Industries, the main objective has been determined as ‘to strengthen the defence industry ecosystem in order to meet the needs of our armed forces and security forces with national technologies and domestic capabilities to the maximum extent with an understanding of continuous development and to increase defence exports, and to ensure the dissemination of the capabilities acquired in the defence industry to the civilian sector’. In line with this objective, in the Strategic Plan, following policies have been taken as basis:

On the other hand, targets in 2024-2028 Strategic Plan have been set ‘to ensure competitiveness and sustainability in sectoral development, to develop technologies and capabilities that will shape the future with national capabilities, and to improve organizational and sectoral capacity’. Within this framework, new projects were initiated in advanced technologies such as artificial intelligence, autonomous technology and cyber security, while steps were taken to expand the industrial base of the Turkish defence industry by establishment of the Defence Industry Competence Inventory (YETEN) and launch of the Industrial Competency Assessment and Support Project (EYDEP).

On the other hand, targets in 2024-2028 Strategic Plan have been set ‘to ensure competitiveness and sustainability in sectoral development, to develop technologies and capabilities that will shape the future with national capabilities, and to improve organizational and sectoral capacity’. Within this framework, new projects were initiated in advanced technologies such as artificial intelligence, autonomous technology and cyber security, while steps were taken to expand the industrial base of the Turkish defence industry by establishment of the Defence Industry Competence Inventory (YETEN) and launch of the Industrial Competency Assessment and Support Project (EYDEP).